Last week I accompanied two of GBMP’s consultants, Bob Elliott and Peter Melnik, to a Shingo Systems Design workshop at Osram, a terrific host site in Hillsboro, New Hampshire. Bob and Peter did all the work. My job, in the spirit of continuous improvement, was just to observe. There are so many things we can see when we have the luxury of just watching – and there is one observation in particular that I’d like to share regarding the paramount importance of TPS methods to the organizational excellence journey.

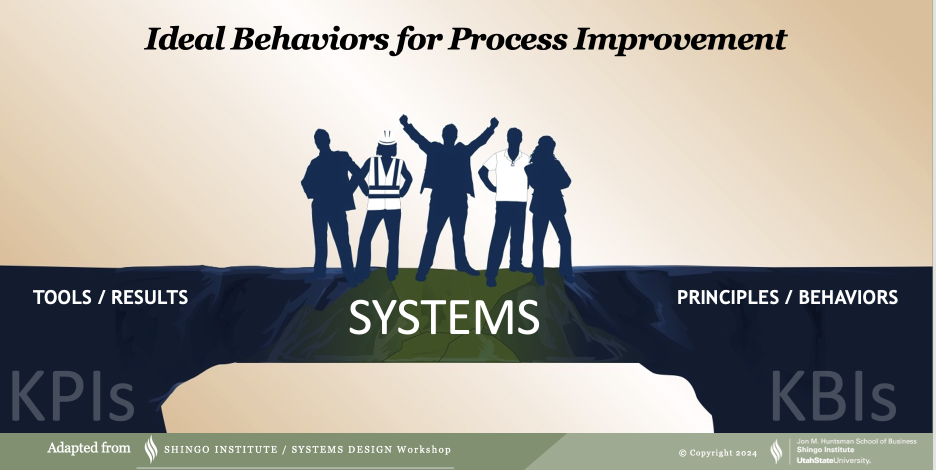

First, for those not familiar with the Shingo Model, the diagram above describes the connection between employees BEHAVIORS (KBI’s, key behavior indicators) and RESULTS (KPI’s, key performance indicators). In this model, SYSTEMS drive behaviors, and IDEAL BEHAVIORS generate great RESULTS by effectively using improvement TOOLS. We may for example deploy a method like 5S workplace organization with these desired outcomes:

- Everything needed to do the job will be at hand.

- The workplace will be spotless and clutter-free.

- Set locations will be standardized across the organization.

- Workplace organization will continuously improve over time.

From these outcomes -- a shared image of ‘what good looks like -- we may ascertain necessary supporting behaviors like:

- Managers and supervisors training the 5S method and then...

- Letting go, encouraging frontline employees to maintain and improve the workplace over time and then...

- Frontline collaboration and engagement to sustain the improvement and recommend improvements as needed.

Expected RESULTS might include:

- Time savings through reduction of motion waste (searching) and

- Defect reduction (set location for parts).

Finally supporting SYSTEMS – the links between KPI’s and KBI’s might include:

- Employee training for the 5S method.

- Allocation of time for improvement.

- Reinforcement of practice through leader standard work.

Now to my observation from last week’s workshop: At one point in the Systems Design workshop attendees were asked to list improvement methods at their companies.

Methods notable by their absence from this list: Heijunka, Standardized Work, SMED, Jidoka, Pull Systems and Continuous Flow – pretty much the guts of the TPS house.

To be sure there are many other improvement methods that were listed, including 5S, visual control, various problem-solving tools, idea systems and huddle boards. But the ‘better methods’ first introduced to the west in 1986 by Shigeo Shingo were notably absent. Reflecting on the few dozen Shingo workshops I’ve presented or attended; it seems that many organizations can describe ‘what good looks like’ for 5S but feel much less comfortable with Just-In-Time or Built in Quality TOOLS. This raises an important question for companies on the Shingo journey. Does your improvement model look like this three-legged stool? Ideal results require ideal behaviors – but the tools to which those behaviors are attached must first be understood and practiced.

To be sure there are many other improvement methods that were listed, including 5S, visual control, various problem-solving tools, idea systems and huddle boards. But the ‘better methods’ first introduced to the west in 1986 by Shigeo Shingo were notably absent. Reflecting on the few dozen Shingo workshops I’ve presented or attended; it seems that many organizations can describe ‘what good looks like’ for 5S but feel much less comfortable with Just-In-Time or Built in Quality TOOLS. This raises an important question for companies on the Shingo journey. Does your improvement model look like this three-legged stool? Ideal results require ideal behaviors – but the tools to which those behaviors are attached must first be understood and practiced.

What does your process improvement stool look like? Please share an opinion.

O.L.D.

PS I am really looking forward to GBMP's annual gathering of hundreds of passionate Lean practitioners, The Northeast Lean Conference, on November 7-8 in Providence RI, and sincerely hope I will see you there. We've put together an exciting agenda - 5 keynotes, 4 concurrent tracks, a dozen benchmarking poster presenters, structured networking and much more - to help your organization achieve its next level of operational excellence. November will be here before you know it, so please don't wait to register. And consider bringing some of your frontline workers to ignite their creativity and desire to participate in your CI initiative.

PS I am really looking forward to GBMP's annual gathering of hundreds of passionate Lean practitioners, The Northeast Lean Conference, on November 7-8 in Providence RI, and sincerely hope I will see you there. We've put together an exciting agenda - 5 keynotes, 4 concurrent tracks, a dozen benchmarking poster presenters, structured networking and much more - to help your organization achieve its next level of operational excellence. November will be here before you know it, so please don't wait to register. And consider bringing some of your frontline workers to ignite their creativity and desire to participate in your CI initiative.

To be sure there are many other improvement methods that were listed, including 5S, visual control, various problem-solving tools, idea systems and huddle boards. But the ‘better methods’ first introduced to the west in 1986 by Shigeo Shingo were notably absent. Reflecting on the few dozen Shingo workshops I’ve presented or attended; it seems that many organizations can describe ‘what good looks like’ for 5S but feel much less comfortable with Just-In-Time or Built in Quality TOOLS. This raises an important question for companies on the Shingo journey.

To be sure there are many other improvement methods that were listed, including 5S, visual control, various problem-solving tools, idea systems and huddle boards. But the ‘better methods’ first introduced to the west in 1986 by Shigeo Shingo were notably absent. Reflecting on the few dozen Shingo workshops I’ve presented or attended; it seems that many organizations can describe ‘what good looks like’ for 5S but feel much less comfortable with Just-In-Time or Built in Quality TOOLS. This raises an important question for companies on the Shingo journey.