A Blog About Understanding The Toyota Production System and Gaining Its Full Benefits, brought to you by "The Toast Guy"

Dogs & Buns

In a humorous moment from Steve Martin's comedy, Father of the Bride, there is a scene where George Banks (Martin) argues with a store clerk that the number of buns in a package is mismatched with the packaged number of hot dogs: “I wanna buy eight hot dogs and eight hot dog buns to go with them; but since no one sells eight hot dog buns, I’m removing the superfluous buns from the package.” According to Banks, the mismatch is caused by some ‘big shot at the wiener company colluding with a big shot at the hot company.’ Perhaps. Or maybe it’s because each of the production processes has been driven independently by local efficiency.

In a humorous moment from Steve Martin's comedy, Father of the Bride, there is a scene where George Banks (Martin) argues with a store clerk that the number of buns in a package is mismatched with the packaged number of hot dogs: “I wanna buy eight hot dogs and eight hot dog buns to go with them; but since no one sells eight hot dog buns, I’m removing the superfluous buns from the package.” According to Banks, the mismatch is caused by some ‘big shot at the wiener company colluding with a big shot at the hot company.’ Perhaps. Or maybe it’s because each of the production processes has been driven independently by local efficiency.

The incident in the supermarket reminds me of a tour some years ago of a golf ball factory to which I invited my teacher, Hajime Ohba. The site had made some nice improvements to reduce overproduction by improving machine setups and converting a system of push production to pull. But they still struggled to keep Kanban supermarkets filled. At each level of production, the variety of sku’s was onerous. As background, for those of us who are non-golfers (not including Mr. Ohba who loved golf), product variety in the golf industry abounds. Any new ball that promises a few more yards on the green can be an overnight success. But product proliferation places a heavy burden on factories with equipment changeovers. In the case of golf ball manufacture, a seemingly simple end item passes through no less than ten machine-intensive operations: from mixing rubber to extruding blanks to molding the core of the ball to grinding it to perfect concentricity, to covering it first with a soft mantel and then a hard shell, to painting to printing to custom logo-ing, and finally to sleeving. Through all of these operations, machine efficiency dictated optimal batch size, which like in Bank’s hot dog and bun example all but guaranteed what Mr. Ohba pointed out were “mismatched indices.” For example, compression molds held forty-eight parts for each shot, while injection molds were optimized for only eight parts. The lots for each were baked into the tooling. Ultimately, none of the process indices matched the final pack-out quantity of three balls per sleeve.

Perhaps these mismatches would be more obvious if the work were manual. Or maybe if the factory was less functionally organized the Mura would be more obvious. “The worst waste,” as Shigeo Shingo once noted, “is the waste we do not see.”

How about in your factory? Are you driven by local efficiency, especially for machine-intensive operations? Please share a story.

O. L. D..

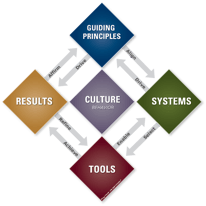

PS Did you know GBMP was the very first licensed affiliate of The Shingo Institute? We have 7 facilitators on our team teaching all six of the institute's six workshops. We figure we've trained more than 7,000 people on The Shingo Model since 2010. Perhaps you've heard of it, but you're not quite ready to commit to a 2-day course? We get that, and if that's the case you should check out our 2-hour virtual seminar, "Overview of The Shingo Model" on March 29 to get a feel for the material and decide if it's for you or not. Short time, short money, potentially huge ROI.

PS Did you know GBMP was the very first licensed affiliate of The Shingo Institute? We have 7 facilitators on our team teaching all six of the institute's six workshops. We figure we've trained more than 7,000 people on The Shingo Model since 2010. Perhaps you've heard of it, but you're not quite ready to commit to a 2-day course? We get that, and if that's the case you should check out our 2-hour virtual seminar, "Overview of The Shingo Model" on March 29 to get a feel for the material and decide if it's for you or not. Short time, short money, potentially huge ROI.