A Blog About Understanding The Toyota Production System and Gaining Its Full Benefits, brought to you by "The Toast Guy"

Robot Day

I responded recently to a LinkedIn post regarding AI-assisted robotic recycling. The sorting speed is so fast, we almost miss each sort in the blink of an eye. Having observed this same activity attempted by humans — and overlooking the upstream potential to avoid this kind of recycling mess at the source (the wasteful consumer) — I’m all over the potential to pass off these kinds of tasks to machines. Humans doing this work must operate at a much slower pace, risk injury, and are not so precise as the AI robot. And of course, humans must also deal with the stench of garbage; these robots, at least, have no sense of smell to distract them from their work.

Today, smart robots are economically feasible for even small companies, and are increasingly deployed to work in concert with human counterparts. Referred to as co-bots, collaborative robots, these machine counterparts share the work in factories, restaurants, warehouses, operating rooms and offices. Given the advancement of artificial intelligence, robotics and multi-sensing technologies, it seems that eventually, no job will be beyond the capability of robots; science fiction is becoming science fact. With the recently apparent shortage of humans to fill jobs this Labor Day, the role of smart robots is on my mind and leading to some whimsical questions; not so much about doing the work, but improving the work:

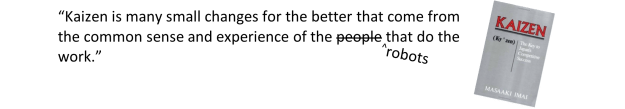

Will smart machines, for example, become smart enough to solve problems? Will their designers build into them what Frank and Lillian Gilbreth called “a motion mind,” i.e., will they examine their own motion, or perhaps the motion of other robot team members, to reduce waste? Robots are subject to the same wastes as humans; e.g., in a poor floor layout a robot must travel the same distance to do the job as its human counterpart. Will AI be imbued with algorithms to identify better flow? Will smart robots analyze and improve their standardized work? Will they collaborate with humans and with each other to brainstorm (sort of) and test ideas? Collaborative improvement presumes a harmonization of different perspectives to create a more robust solution than would be available from any single contributor. Referring to Masaaki Imai’s definition of Kaizen (my favorite), can it evolve into this?

In the absence of hands-on human experience of the people who do the work, what context will this definition have? And, what facility can be given to smart robots to create the will to improve, the most basic condition, according to Shigeo Shingo, for improvement. So-called human qualities such as “constructive dissatisfaction with the status quo” are not necessary to do the job, but are fundamental to improving the job. Joseph Weizenbaum, an early AI pioneer, argued that such qualities are not transferrable to machines. While his AI psychoanalyst simulation, Eliza (Circa, 1966), was designed to mimic a therapist’s response to human discourse, Weizenbaum warned that “no computer, can be made to confront genuine human problems in human terms.” This warning has been echoed ever since in dystopian science fiction literature and cinema. How much longer will this be fiction?

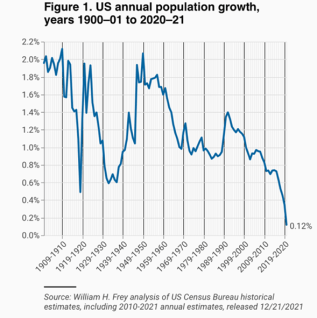

These whimsical questions may not be immediately relevant. In a world where there is currently a shortage of humans to fill jobs, robots offer a practical solution. As I write this post, there are currently twice as many job openings in the U.S. as job applicants. While much attention has been given to the acute shortage, the rate of U.S. population growth (Fig. 1) has decreased steadily since 1990 and is nearly flatlined, with many states showing a net decrease in population. No doubt, the people shortage has been exacerbated by COVID-19, but the issue is chronic.

In view of this persistent need, what might we expect from the inexorable evolution of science fiction to science fact? With the current pace of technical advancement and likely long-term labor shortage, what will dissuade employers from replacing most human labor with robots? Rosie the Robot, after all is an investment, while Rosie the Riveter is a variable expense; they each hit the bottom line very differently. The allure of a productive resource that is apparently tireless, reliable and requires no benefits may simply be overwhelming – almost too good to be true. In the words of pioneer systems thinker Russell Ackoff,

“Managers are incurably susceptible to panacea peddlers. They are rooted in the belief that there are simple, if not simple-minded, solutions to even the most complex of problems. And they do not learn from bad experiences. Managers fail to diagnose the failures of the fads they adopt; they do not understand them.”

While AI and Robotics are surely not panaceas, applying them as a total solution may just be. I visited a company recently, for example, that utilizes smart robots to move inventory miles between multiple storage locations rather than improving layout to consolidate stockrooms. An engineer bragged to me “We even programmed it to ride the elevator.” Dr. Shingo called this superficial improvement, automating waste rather than eliminating it.

For those of us who subscribe to Taiichi Ohno’s idea that “95% of the elapsed time between paying and getting paid” is waste, the current labor shortage presents a huge impetus to develop an army of problem solvers to eliminate it – a workforce with the will and creativity to reap greater benefits from Lean. While the vision of TPS is human development, certainly this includes thoughtful use of IoT, just as it has included mechanization and automation. But will Lean thinking inform the designers of AI? Will they go to the Gemba to learn? Will they regard employees as the most valuable resource? Will they be systemic thinkers? Or will they, as Shigeo warned, just be table engineers or catalog engineers, distant from the process and perhaps a little too enamored of the technology? That story is not yet written. Will it be as dystopian as the science fiction predicts, or a golden age for productivity and human development? And how can Lean thinkers influence the latter?

What do you think? Please share some thoughts.

O.L.D.

P.S. Speaking of human development, I hope you’ll be able to join us on September 28-29 in Springfield, Massachusetts, for the 18th Annual Northeast L.E.A.N. (Lead, Enable And Nurture) Conference. Four great keynotes, four tracks of breakout sessions, a Lean Lounge with poster presentations, and a Lean After Dark networking session. AND – if you can’t make it in person, all sessions will be live-streamed on Whova and recorded for later viewing. You can check out the agenda here: Conference Agenda.