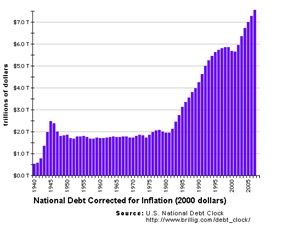

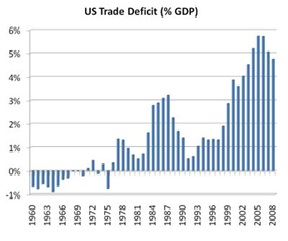

Gross numbers reflecting American productivity can be misleading. When American companies outsource production, the labor “expense” is replaced with the “asset” of inventories purchased elsewhere. While this results in a gross statistical improvement to labor productivity, its overall impact on economic strength is insidious. Consider, for example, these two graphics in particular for the period from 1985 onward, the point in time when off-shoring became the “means to stay competitive.”

The graph on the left is our national debt, the one on the right, our trade deficit.

I call this condition TDD: Trade Deficit Syndrome [Disorder.] America suffers from TDD.

This is not a condition that can be medicated. But, through Lean, we can effect major behavior modification. That is the message of Made Lean in America, our 2011 Northeast Shingo Conference: When goods and services are made in America, we make America strong; and conversely, relinquishing our productive capability causes not only an outflow of American jobs, but also a growing, precipitous national debt.

Is your company suffering from TDD? Come hear about the cure on October 5-6, 2011 in Springfield, Massachusetts.

O.L.D.

BTW: When I come in contact with an organization that is producing its product here in the US with mostly US made parts, that’s a big deal. When that company is then selling 75% of those products outside of the US, that’s a really big deal. Brookfield Engineering Labs is doing just that, shipping over 75% of their made-in-America products outside of the US. How do they manage that and how has Lean helped them? Bob Bishop will share their story at our conference. Here’s a sneak preview of his presentation: (Click the link or the arrow button to listen)

http://wp.me/p1cOUS-9P

[audio http://oldleandude.com/wp-content/uploads/2011/09/everybody-everyday-bob-bishop-9-9-11.mp3]